Plot Upper and Lower Control Limits in Excel

Lower control limit Two other horizontal lines called the upper control limit UCL and the lower control limit LCL are also shown on the chart. Cell name-3 standard deviation sigma.

Best Excel Tutorial Upper And Lower Control Limits In Excel

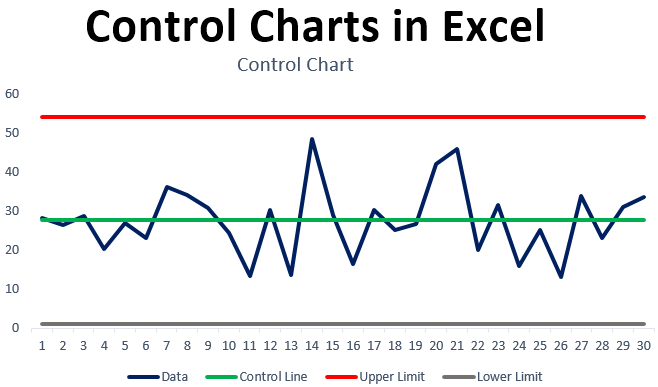

Control limits are the horizontal lines above and below the center line that are used to judge whether a process is out of control.

. A124 A217 A39 A44 Based on this the MEAN135 and STANDARD DEVIATION 881286937760152 I want to create a formula to calculate the UCL and LCL When I use MINITAB I get UCL3123 LCL-423. Lower control limit. The upper and lower control limits are based on the random variation in the process.

First lets enter the values for our sample data. Ensure you are using the right formula. By comparing current data to these lines you can draw conclusions about whether the process variation is consistent in control or is unpredictable out of control affected by special.

2 Determine an appropriate. LCL CL 3S. Calculate the Upper Lower Limits.

The formula for sigma depends on the type of data you have. These are simply 1 sigma 2 sigma and 3 sigma from the center line. 1 Determine what actions management should take.

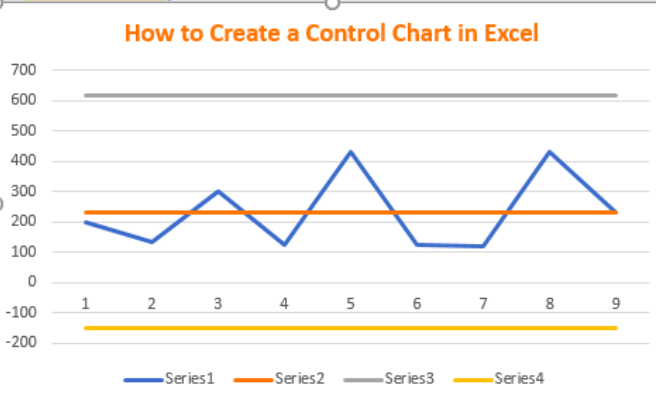

The formula represents 3 standard deviations above and 3 standard deviations below the mean respectively. Calculate the upper and lower control limits UCL LCL using the following formula. Hi All I have a range of numbers.

How do you calculate upper and lower control limits in Excel. How to create an excel chart with a grey area showing the upper and lower limits. Change the line color to red and set the width to 5 pts.

The graph also will be divided into zones. A Calculate the upper and lower control limits and plot the corresponding X-bar chart. The upper control limit is one key to process improvement actions.

LCL CL 3S. Change the chart title. Like the upper control limit QC professionals use three standard deviations or Sigma below the centerline.

A random sample of 12 units were selected every day and their average and ranges in mm were recorded. Please see the data in the excel file attached see problem3 worksheet in exam2-dataxlsx. Your chart should look similar to this one.

Calculate the Upper Control Limit UCL which is the mean of means plus three times the standard deviation. There is no built in capability in Excel or in the ToolPak to do what you want. One can create a control chart in Excel with relative ease.

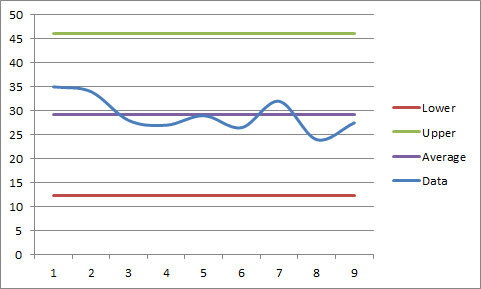

The upper control limit formula will vary depending on the statistic average range proportion count that is being plotted. LCL is visible as a orange line and UCL is a grey one. Adding upper and lower control limits in chart.

Or is there an Add-Ins ToolPak to create a simple run chart aka r statistical process control chart. These lines are determined from historical data. Do the same for the upper limit line.

How to create an excel chart with a grey area showing the upper and lower limits. The Excel formula for calculating LCL is. To create a Six Sigma Control Chart in.

The following step-by-step example shows how to create a statistical process control chart in Excel. Next we can use the following formula to calculate the mean value of the dataset. The chart consists of four lines -- the data a straight line representing the average as well as an upper control limit.

By default Minitabs control limits are displayed 3 standard deviations above and below the center line. Use the standard UCL formula and the control chart table to calculate the UCL. Do I use Chart Wizard and add in the upperlower control limits or the target SLA goal as additional series or should I use a pivot table chart.

If needed multiple control limits can be included in the control chart so as to get early indicators of minor process control limit breaches. These control limits are chosen so that almost all of the data points will fall within these limits as long as the process remains in-control. UCL CL 3S.

In this example type F73F8 without quote marks in cell F9 and press Enter Calculate the Lower Control Limit LCL which is the mean of means minus three times the standard deviation. This example type F7 3F8 without quote marks in cell F9 and press Enter. The minor controls limits in such a case are set narrower than the major control limits and therefore will be violated earlier than the major ones.

Right-click the first lower limit line and choose Format Data Series from the menu. You can calculate the lower control limit in a control chart from the centerline and the Sigma lines for the data. The figure below illustrates this.

Create an appropriate control chart with upper and lower control limits plot the data in a Control Chart using Excel and determine if the process is in control. A control chart always has a central line for the average an upper line for the upper control limit and a lower line for the lower control limit. 3 sigma Upper Control Limit UCL - 3 sigma Lower Control Limit LCL Why are there so many formulas for sigma.

Control Charts In Excel How To Create Control Charts In Excel

Create An Excel Control Chart To Analyze Data Pryor Learning

Comments

Post a Comment